This is the next in a series of posts by recipients of the Career Services Summer Funding grant. We’ve asked funding recipients to reflect on their summer experiences and talk about the industries in which they’ve been spending the summer. You can read the entire series here.

This blog is by Pele Colins, SEAS’ 17 and Steve Rybicki, SEAS ’16.

The company with whom we were offered summer work is called Robohand, which is located in Pretoria, South Africa – not far from Johannesburg. Robohand works out of a large house, as opposed to an office building, called House 4 Hack, an incredible technological innovation center. Doctors (PhDs) and countless intellectuals come to the house every day and work on a number of different projects. Aside from Robohand, these projects include 3D printer development, development of quadcoptors and drones, advanced computer science and software development, etc…

Robohand was created back in 2012 by a South African carpenter and innovator named Richard Van As, who created the idea for the hand after losing a few of his fingers in an accident. What originally began as on opportunity to rebuild his own fingers expanded into a company helping individuals all over the world. In fact, a Robohand product exists in every country around the world, except three!

Robohand was created back in 2012 by a South African carpenter and innovator named Richard Van As, who created the idea for the hand after losing a few of his fingers in an accident. What originally began as on opportunity to rebuild his own fingers expanded into a company helping individuals all over the world. In fact, a Robohand product exists in every country around the world, except three!

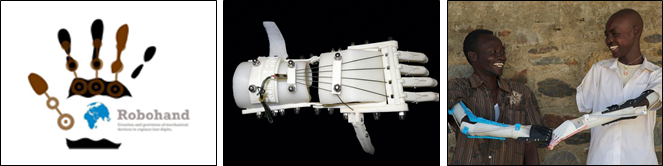

According to the website’s press page, “Robohand creates 3D printed and aluminum CNC machined, anatomically driven, custom fitted, mechanical devices to help limb different individuals as an alternative to standard prosthetics.” The company’s technology has been able to help finger, hand, and arm amputees as well as individuals born with Amniotic Band Syndrome (ABS), a congenital disorder which inhibits the development of the hand and/or fingers. 3D printing technology allows for the prosthetic’s parts to be manufactured incredibly quickly and cheaply; thus, an entire, partially-functional hand can be manufactured in only a few hours and at a fraction of a cost of traditional prosthetics. The functional Robohand prosthesis, when coordinated with the movement of the wrist, allows the individual to grasp and release items such as a ball, cup, pencil, etc. Adults have been able to regain partial use of their lost extremities and limbs; children born with defects have been able to perform actions and pursue goals they otherwise would have found impossible. Robohand is rewriting the futures for children and adults around the world.

In March, we Skype-interviewed with Leonard Nel, the Director of Communications for Robohand. Through our conversation, it was apparent that the Robohand organization would benefit from additional support. Demand for the product is currently exceeding its supply, both in material and manpower to produce the devices. Leonard also indicated that, in addition to printing and fitting Robo-fingers, hands, and arms, we would also be involved in the development of new Robohand technology. The company is in the process of creating a new line of 3D printers, called the RoboBeast. The RoboBeast’s larger, more rugged design allows the technology to be more easily transported to areas of the world where people most need the devices printed. Additionally, in our role with the company, we would be involved in the design and creation of Robohand’s most recently conceptualized products – Robo-feet and legs.

What’s also incredible about Robohand is that their prosthetic designs and computer files are all open-sourced and available for free online. Anyone with the correct software and access to a 3D printer – anywhere in the world – can print and assemble one of these hands.

In our six weeks of work with the company, we were involved in the design and assembly of Robohand’s first prototype for a RoboLeg, developed a new type of mechanically driven finger and hand, and developed new parts for the RoboBeast Printer. In our free time, we also worked other groups within the House 4 Hack, designing a 3D printable, collapsible quadcoptor with adjustable wing positions, a 3D printed glider, and a 3D printed camera-box which held the lenses and circuit-boards for a camera that recorded photosynthesis. Really cool stuff. We primarily were responsible for designing the parts and components using CAD software (Computer Aided Design), printing our designs with the 3D printers, assembling and testing them, and correcting our designs as was necessary.

In our six weeks of work with the company, we were involved in the design and assembly of Robohand’s first prototype for a RoboLeg, developed a new type of mechanically driven finger and hand, and developed new parts for the RoboBeast Printer. In our free time, we also worked other groups within the House 4 Hack, designing a 3D printable, collapsible quadcoptor with adjustable wing positions, a 3D printed glider, and a 3D printed camera-box which held the lenses and circuit-boards for a camera that recorded photosynthesis. Really cool stuff. We primarily were responsible for designing the parts and components using CAD software (Computer Aided Design), printing our designs with the 3D printers, assembling and testing them, and correcting our designs as was necessary.

We very much hope to continue working with Robohand remotely from the United States, designing and printing parts here and collaborating with the group still in South Africa. It would also be great to be able to return to South Africa next year and continue the work we started. We are very excited, not only for the future of Robohand, but for the future of 3D printing in general. The field is incredibly new, is quickly growing, and has tremendous potential. There are so many different directions and opportunities that the future can bring. It is also truly inspirational that some companies out there are using their skills and resources not to make a profit for themselves, but rather to design products that actually help people and solve real life problems.

We very much hope to continue working with Robohand remotely from the United States, designing and printing parts here and collaborating with the group still in South Africa. It would also be great to be able to return to South Africa next year and continue the work we started. We are very excited, not only for the future of Robohand, but for the future of 3D printing in general. The field is incredibly new, is quickly growing, and has tremendous potential. There are so many different directions and opportunities that the future can bring. It is also truly inspirational that some companies out there are using their skills and resources not to make a profit for themselves, but rather to design products that actually help people and solve real life problems.